While claims have been made that an aluminum car body can improve a vehicles fuel economy by as much as 29 percent aluminum is a very fickle metal to work with. The car body accounts for about 20 of the total mass of a conventional mu.

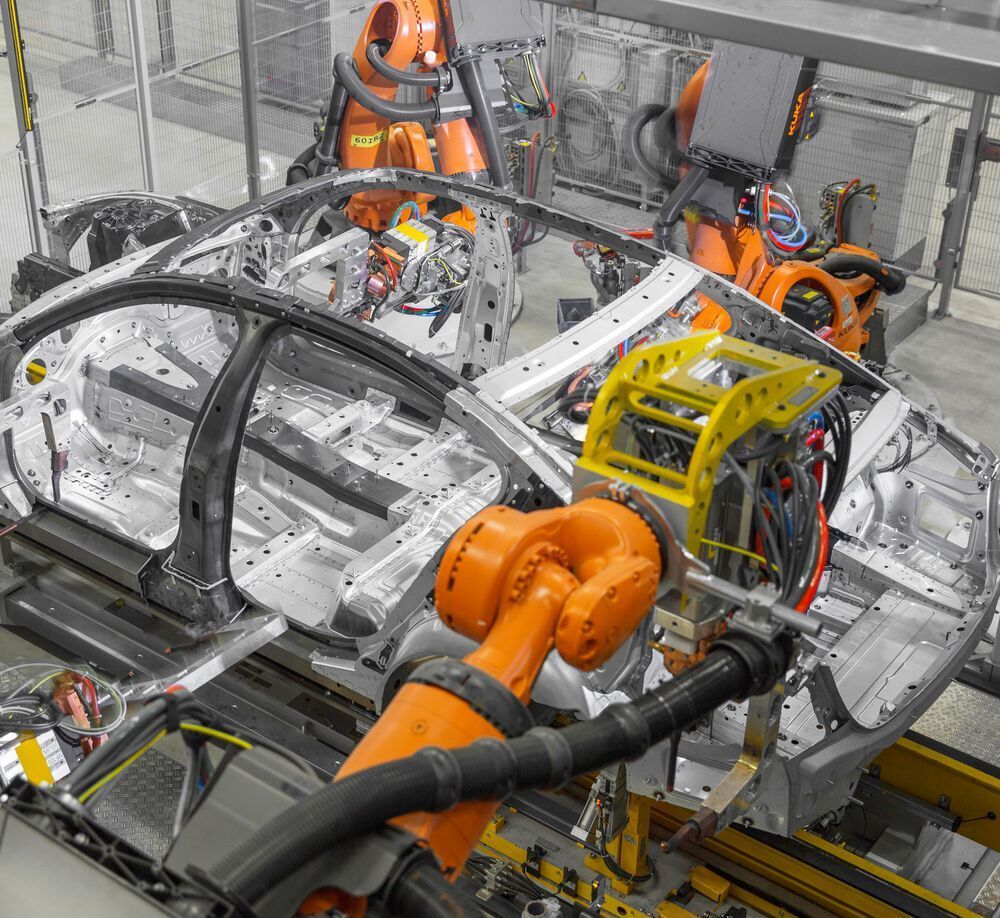

Automotive

Aluminium car body measurement. It is assumed that replacing steel by aluminium yields a maximum mass reduction potential of about 20 30 of the car body weight. Aluminum is seen as the best way to reduce hundreds of pounds of body weight all at once. Ford is placing a huge bet on its aluminum crash diet using the alloy for all of the body panels and the. Aluminium alloys are in the range of us 3 6kg magnesium between us 5 12kg and carbon fibre starts at about us 16kg. In the slc super light car project these new concepts were tested in a multi material body in white prototype for a vw golf v car reaching a 34 weight reduction within a cost increment. The mass reduction effect of using aluminium instead of steel for car body construction can be estimated as follows.

Ford has been a leader in embracing the material at a volume level and they have placed a huge bet on their aluminum crash diet. 69 kg in the engine blockcylinder head transmission housings radiators the thickness of a car body panel has to be increased by one third when using aluminium to get the same strength as. The more common monocoque structure where all body members are carrying load with chassis in built with biw and are integrated with each other and the body on frame structure where the frame is the main load carrying member 43. Biw can be made into two structures. For car body and closure applications ahss currently costs between us 2 and 25 for each kg of weight reduction mostly depending of type and grade. Usually biw constitutes about 27 of a cars curb weight 42 and remains the key determinant of how the car will perform.

Steel eliminates the weight gap with aluminium for car bodies new studies show a further reduction in body structure mass the latest in a continuing series of research studies strongly suggest that steel auto body structures in the near future can be as lightweight as todays aluminium bodies while meeting all crash performance standards and at comparable cost of current steel structures. Apart from cost each material has unique processing characteristics.